Sand is coarse, rough, irritating, and it gets everywhere. It's also the key ingredient in solar panels.

If you're looking to install a solar system in your home so you can say goodbye to your electric bill -- and the inflation that keeps pushing it up -- you should be grateful for sand.

Now, you can't just go outside, throw a bunch of sand on your roof and pray for energy to flow through it into your power outlets -- far from it. While sand is an essential raw material for producing solar cells, not every kind of sand will do. The sand used for solar cell production must be rich in silicon dioxide and meet exacting standards to ensure the resulting solar cell most efficiently converts sunlight to electricity.

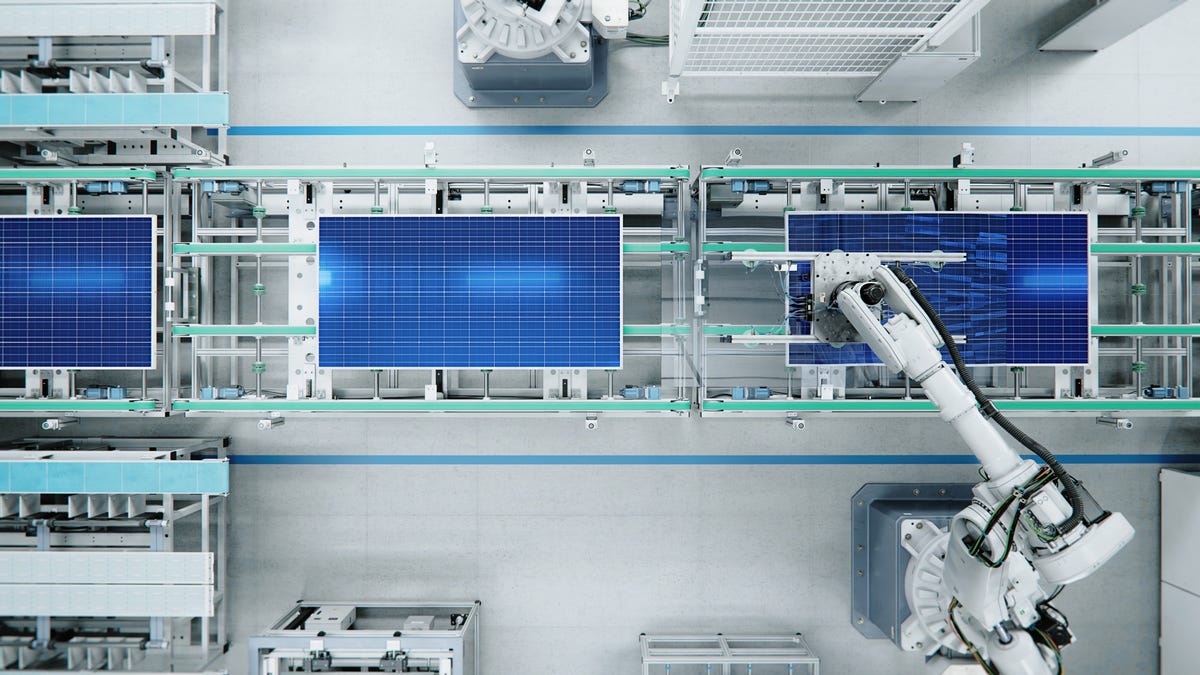

It also takes a highly sophisticated manufacturing process to create efficient solar cells, the building blocks of the solar panels you see on rooftops everywhere.

Here's what goes into a solar panel.

What are monocrystalline solar panels made of?

The two most common types of household solar panels -- monocrystalline and polycrystalline -- both start with sand that has a high silicon dioxide content being heated and purified to form blocks called ingots, Rohit Kalyanpur, CEO of Silicon Valley-based solar technology company Optivolt, told CNET.

For monocrystalline solar panels, individual wafers are cut from a single ingot. The ingots used for monocrystalline cells have a distinctive black appearance and uniform cell structure. Solar panels made from monocrystalline solar cells are the most efficient, with ratings ranging from 17% to 22%, and offer the best performance. As of 2021, more than half the residential solar panels installed in the US had efficiency ratings above 20%, compared with 0.6% a decade ago, according to the Lawrence Berkeley National Laboratory's Tracking the Sun report.

The average cost of these panels is between $1 and $1.50 per watt, but prices may differ depending on location. Monocrystalline panels have a 25-year useful life, a moderate temperature coefficient -- how well they perform on hot days -- and an all-black appearance.

What are polycrystalline solar panels made of?

Polycrystalline solar panels are made from a combination of several silicon crystals. The manufacturing process involves melting multiple silicon crystals and forming them into wafers. These blended wafers have a distinctive bluish hue, due to the random orientation of the silicon crystals. Because the wafer has a nonuniform cell structure, polycrystalline solar cells are less efficient than monocrystalline solar cells. Therefore, solar panels made from polycrystalline solar cells have efficiency rates ranging from 15% to 17%.

The average cost of these panels ranges from 90 cents to $1 per watt. The temperature coefficient of polycrystalline panels is worse than that of monocrystalline panels, meaning they'll perform worse when it's hot, but they can still function for up to 25 years. As a result, these panels are great for budget-conscious homeowners.

What are thin-film solar panels made of?

Thin-film solar panels are made by putting a thin layer of photovoltaic material, such as amorphous silicon, cadmium telluride (CdTe), or copper indium gallium selenide (CIGS), on a material like glass or plastic. These panels are known for being both flexible and light, making them suitable for applications where traditional panels may not be feasible, such as on curved surfaces or portable devices. However, thin-film panels are generally less efficient than both monocrystalline and polycrystalline silicon panels, while costing $1 to $1.50 per watt.

How are solar panels made?

Now that we've covered how different types of solar cells are made, you're probably wondering how solar panels themselves are assembled. Here's a step-by-step outline of the process.

- Step 1: Silicon purification and ingot formation: Sand with a high silicon content is refined to remove impurities and produce high-purity silicon. The silicon is melted and formed into cylindrical ingots.

- Step 2: Wafer slicing: The silicon ingots are sliced into a precisely measured and prespecified thickness with a diamond-edged saw. The thickness of the wafer is carefully controlled to optimize the balance between light absorption and electrical conductivity. These wafers are the "foundation of each solar cell," Kalyanpur said.

- Step 3: Cell processing: The wafers are then put through a series of treatments to enhance their photovoltaic properties. The treatments include a texturing process to increase light absorption. Metal contacts are added to the front and back of each cell to allow the cells to conduct electricity.

- Step 4: Solar cell assembly and encapsulation: The solar cells are assembled into a solar panel by connecting them in series or parallel configurations. The configuration will determine the desired voltage and current output. The cells are then encased in durable glass or another transparent material. The encased cells are then attached to a frame.

- Step 5: Integration of electrical components: The junction box and other electrical components are added to the panels. These components enable the solar panel to transmit the electricity it generates to the inverter and charge controller.

Solar panels undergo a rigorous quality assurance process at every stage of the manufacturing process, including after assembly. This quality assurance process helps to ensure that each component meets the required standards for performance and reliability.

Are solar panels safe?

You should always have a healthy dose of skepticism and concern regarding any equipment, but you'll probably have nothing to worry about as long as they are used as originally intended. But if they're misused or damaged during installation, there could be some cause for concern.

Solar panels can include some materials that might be classified as hazardous, according to the Environmental Protection Agency. Different types and manufacturers of panels have different levels of potentially hazardous chemicals, such as lead and cadmium. These are typically part of semiconductors or solder.

"Solar panels are safe and do not pose a significant risk to human health or the environment," said Kalyanpur. "While some toxic materials are used in the manufacturing process, similar to the presence of … cobalt in phone batteries, these materials are safe as long as they are not ingested and are properly disposed of or recycled at the end of their life cycle. Most solar panels are made from silicon, a nontoxic and abundant element that poses no risk to human health. As long as solar panels are properly handled, recycled, or disposed of at the end of their life, people should have no concerns regarding health or safety."

More on solar panels

Article From & Read More ( How Sand Becomes Solar Panels - CNET )https://ift.tt/h5afmyS

Technology

No comments:

Post a Comment